Cookie Consent

We use cookies to give you the best online experience. By using our website you agree to our use of cookies in accordance with our Cookie Policy. Feel free to read our policy.

There are three common positions in which a door closer can be mounted, each one is dependent upon the type and use of the door.

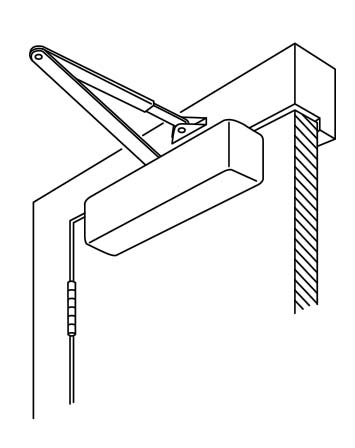

Fig.1 - DOOR MOUNTED PROJECTING ARM, PULL-SIDE

The most common application provides a high degree of door control and range of adjustment. The closer is mounted on the pull side of the door with the arm mounted on the frame. When the door opens the arm passes over the door.

Example;

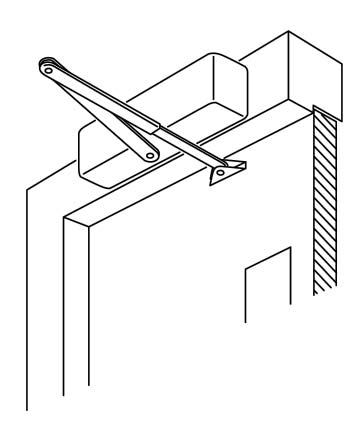

Fig.61 - TRANSOM MOUNTED PROJECTING ARM PUSH-SIDE

The closer is mounted on the frame above the door. The foot is mounted on the push side of the door. This position is intended for external doors opening outward to protect the closer from external elements.

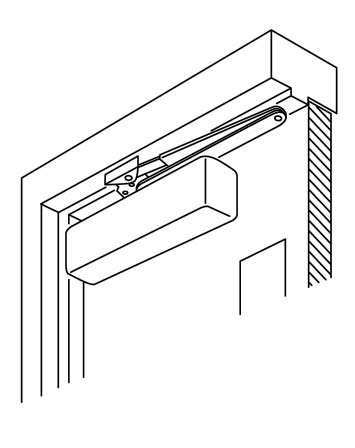

Fig.6 DOOR MOUNTED PARALLEL ARM, PUSH-SIDE

The closer is mounted on the push side of the door. When the door opens, the closer arm swings with the angle of the door. This position stops the closer protruding into the room and is suitable for use on narrow door frames.

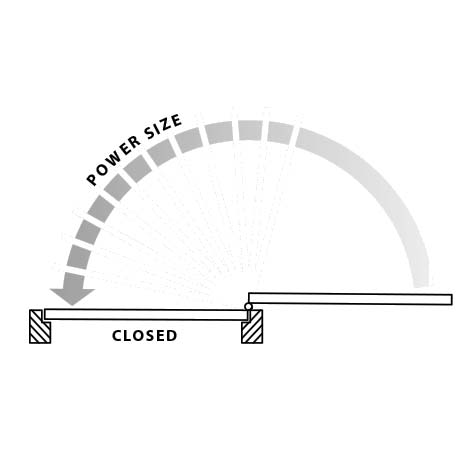

POWER SIZE

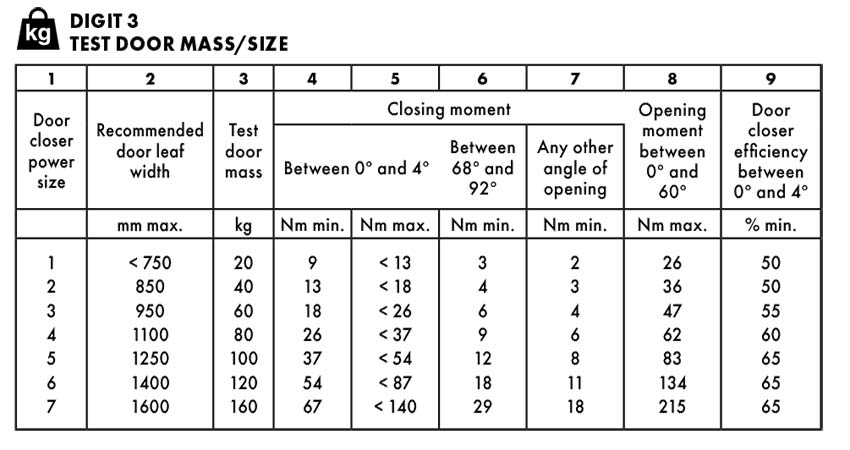

The power size of a door closer is measured in accordance with the closing torque, which is achievable during the closing cycle.

The BS EN 1154 Standard classifies closers from a Size 1 through to a size 7 and recommends the use in accordance with the door width and door mass (weight). Power Sizes can be fixed, selectable or adjustable.

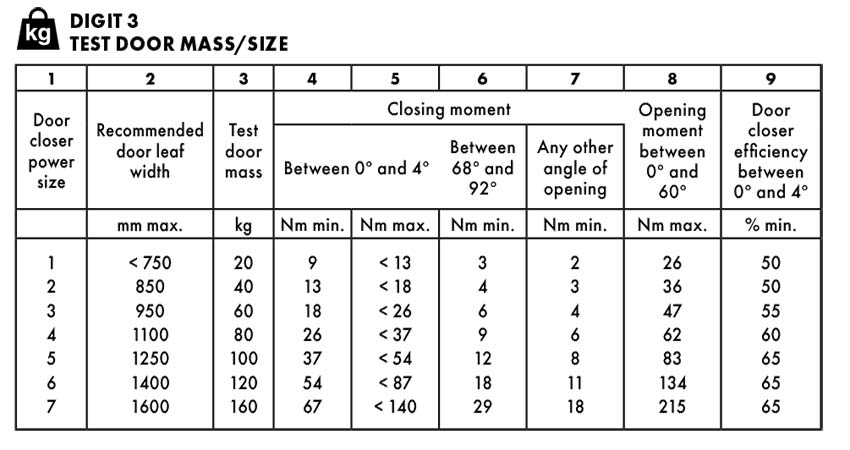

The following table in column 1 illustrates the door mass and size for each door closer power size rating. For example, a power size 3 door closer is suitable for doors up to 60kgs with a door width of 950mm etc.

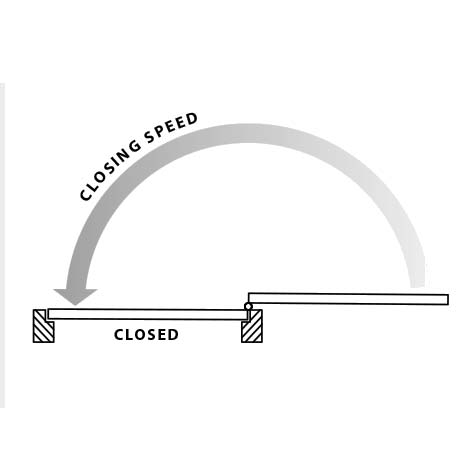

ADJUSTABLE CLOSING SPEED

Controlled door closers offer adjustability to the speed which the door will operate, the closing speed has an adjustment from the maximum opening angle through to the last 10 to 15º.

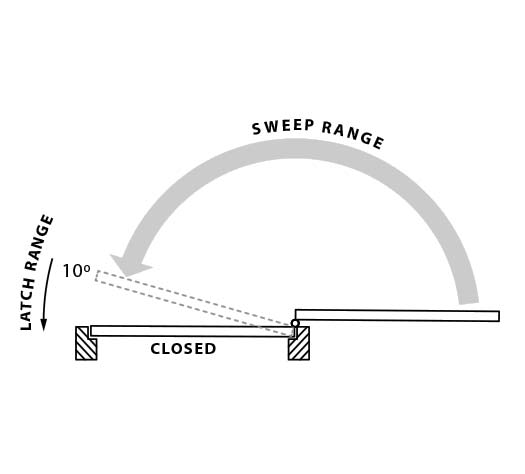

ADJUSTABLE LATCH ACTION

This allows speed adjustability on the last 10 to 15º to assist with overcoming latches and seals ensuring the door closes completely. For example, the door may need to increase speed to close the door on the last closing inch of the door for the door latch to engage into the latch striker plate.

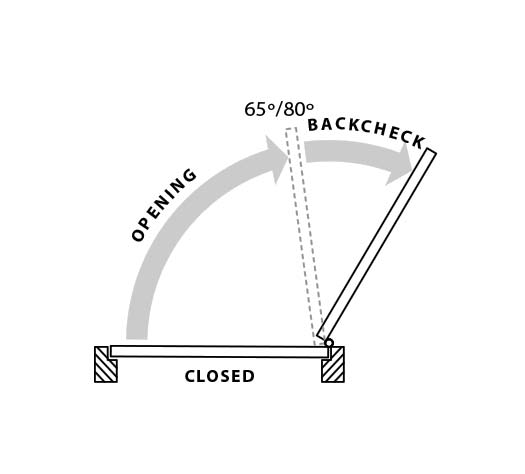

ADJUSTABLE BACKCHECK

The backcheck function slows the speed of the door whilst in the opening cycle, the function is to prevent damage from being caused to the door, associated hardware or adjacent walls in the event of the door being flung open (Backcheck is not an alternative to a door stop).

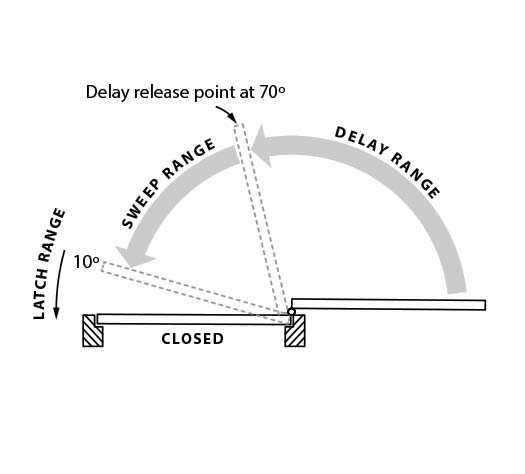

ADJUSTABLE DELAYED ACTION

The delayed action function slows the first part of the closing cycle down. Its function is particularly useful for disabled / elderly who may need additional time to pass through the doorway, delayed action normally releases around 70º where the standard closing speed will then commence.

All dedicated fire-resistant doors should be fitted with a door closer that is successfully tested to BS EN 1154. A closed fire-resisting door is designed to withstand attack by fire for a specified period of time, installation of a door closer will ensure that the door is mechanically closed when not in use.

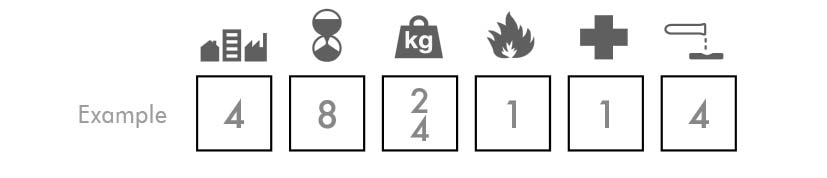

BS EN 1154:1997

This is the European standard for the performance of controlled door-closing devices. It uses a 6-digit coding system to give clear details on the capabilities and performance levels of what the specific door closer model has been tested and approved to. This is an example of a door closer rating to BS EN 1154:1997 and below is an explanation of what this means.

This falls into two grades;

Grade 3 - For closing doors from at least 105 degrees opening.

Grade 4 - For closing doors from 180 degrees opening.

In this example, we have a classification of Grade 8 which represents 500,000 test cycles. This means the door closer has been operated 500,000 times and is still functioning correctly under test.

This states what door size the door closer has been certified for use on. In this case it would be a door from a closer power size 2 to 4 which is doors from 20 to 80 kgs with leaf width from 850mm to 1100mm.

The table below illustrates door sizes in relation to a door closer power size;

Grade 1 = Suitable for use on fire/smoke door assemblies.

Grade 0 = Not suitable for use on fire/smoke door assemblies.

Only 1 grade is available here as all door closers are required to meet the essential requirement of safety in use.

Five grades of corrosion resistance are identified according to EN 1670:

Grade 0 – No defined corrosion resistance

Grade 1 – Mild resistance

Grade 2 – Moderate resistance

Grade 3 – High resistance

Grade 4 – Very high resistance

We stock a comprehensive range of door closers which can be viewed here;

https://www.simplydoorhandles.co.uk/door-closers